The handling of falsified medicinal products (FMDs) is a critical part of compliance with EU Good Distribution Practice (GDP) guidelines. The EU GDP requirements, particularly under Directive 2001/83/EC as amended, and Commission Delegated Regulation (EU) 2016/161, address the detection, prevention, and management of falsified medicinal products within the supply chain.

At MVS Pharma, our commitment to these regulations reflects our dedication to delivering authentic and high-quality medicines. This article outlines the EU GDP requirements for handling FMDs and how MVS Pharma implements these measures.

Table of Contents

What Are Falsified Medicinal Products?

Falsified medicinal products are those that deliberately or fraudulently misrepresent:

- Identity: Incorrect ingredients, dosage, or packaging.

- Source: Fake manufacturer details or origin claims.

- History: Counterfeit batch numbers or unauthorized distribution pathways.

They pose significant risks to patients and the pharmaceutical supply chain, necessitating stringent measures for detection, prevention, and management.

How MVS Pharma GmbH Ensures Compliance

We have developed a system to manage the risk of falsified medicinal products. Our procedures are aligned with EU GDP standards and according to our operational needs.

Supplier Qualification:

Supplier selection holds significant weight, considering the reliance of pharmaceutical companies on suppliers for crucial materials, products, and services. MVS Pharma selects and thoroughly evaluates the supplier’s capabilities and compliance with a due diligence approach

By evaluating them, we gain insight into the supplier’s ability to consistently manage and improve quality, reducing the likelihood of deviations that could lead to the risk of falsified medicinal products.

Read more about it in our article “Quality-Driven Supplier Selection at MVS Pharma.”

Detection and Verification:

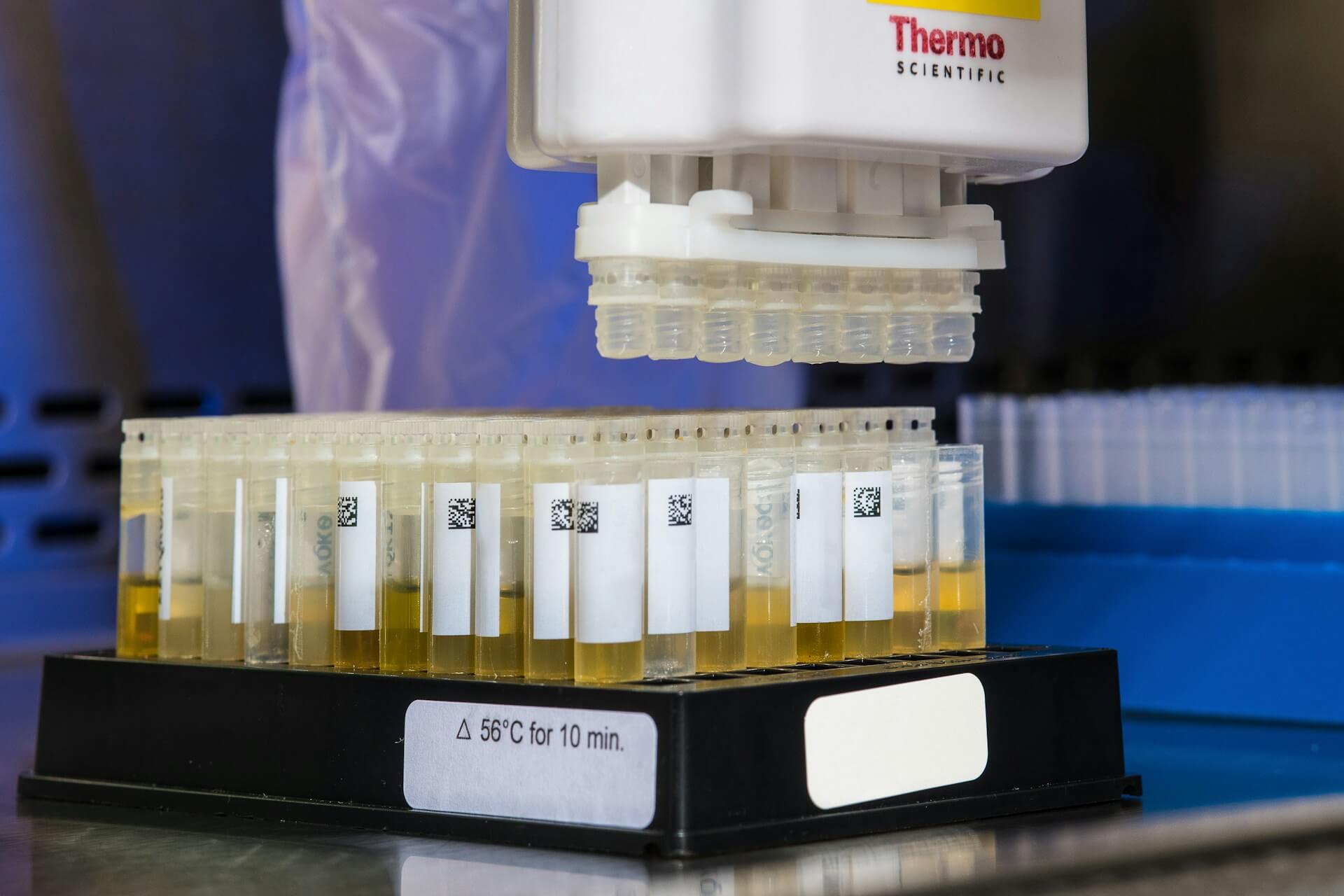

We conduct visual inspections of packaging and labeling and verify unique identifiers (UIs) on outer packaging, as required by Regulation (EU) 2016/161. If any discrepancies are found, an immediate investigation or corrective action is taken.

Secure Quarantine Facilities:

A designated and secure quarantine area in our warehouse ensures that suspected falsified products are safely segregated. Moreover, clear labeling and controlled access prevent mishandling.

Staff Training Programs:

Our team undergoes regular GDP compliance training, including simulations to identify and manage falsified products. Our RP and QMR execute the training as per the Training Calendar. All trainings’ effectiveness is evaluated, and feedback sessions help us refine our processes continually.

Traceability and Documentation:

We utilize a state-of-the-art tracking system of an external company (Odoo), which helps us to ensure full traceability of every product batch in our supply chain.

Collaboration with Authorities:

MVS Pharma maintains open communication channels with regulatory authorities, ensuring timely reporting and resolution of any incidents. Moreover, we also immediately coordinate with healthcare professionals if the product has been dispensed to patients.

Conclusion

The fight against falsified medicinal products is a critical priority for the pharmaceutical industry and regulatory authorities alike. The challenge of falsified medicines demands a proactive and innovative approach. At MVS, we go beyond compliance by establishing inspection protocols, implementing Good Distribution Practices, and staff training into our operations.

We remain committed to leading the way in protecting patients and preserving trust in pharmaceutical products. Together, through continuous improvement and adherence to best practices, we contribute to a safer global healthcare system.

Disclaimer:

As a service to our readers, MVS Pharma GmbH publishing provides access to our library of archived content in our blog. Please note the date of the last review or update on all articles. No content on this site should ever be used as a substitute for direct medical advice from your doctor or other qualified clinician.

MVS Pharma GmbH will soon be launching an omega-3 dietary supplement onto the European market that has been developed for the highest quality standards in terms of oxidation avoidance and, therefore greatest bioavailability. In addition, in vitro studies are currently underway at the University of Ulm, in which Professor Dr. Rüdiger Groß tested a patented mouth and nose spray (Virudol) that can eliminate various flu viruses based on natural substances.

In addition, MVS has a wholesale license and has specialized in sourcing much-needed medicines such as Amoxicillin, Salbutamol, etc. from India through its local branch with a focus on local quality and safety testing, compliance with international GMP regulations and the highest quality level of user security (examples of local language brochures, identical units of measurement, batch control and full tracking, etc.).